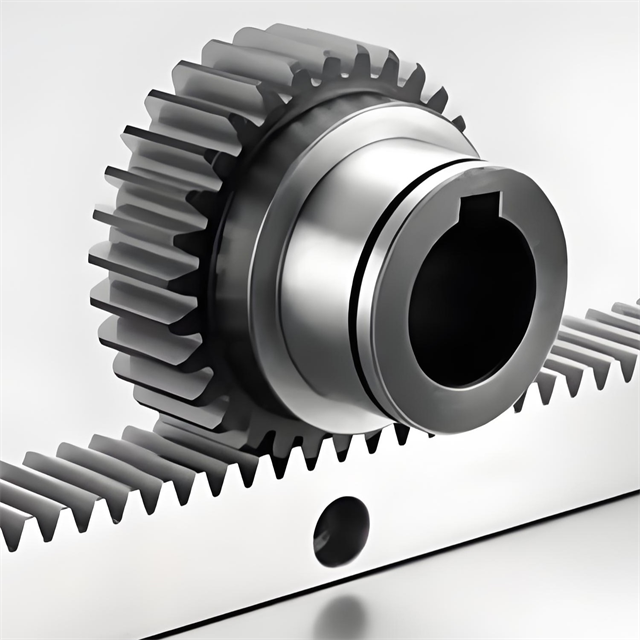

In the competitive landscape of industrial manufacturing, the need for high-performance components is paramount. Spur gear racks are an integral part of many industrial systems, providing the means to convert rotational motion into linear motion with precision and efficiency. We specialize in manufacturing spur gear racks that are engineered to deliver outstanding performance in even the most demanding industrial applications.

| Availability: | |

|---|---|

| Quantity: | |

Our spur gear racks are designed with a focus on performance, durability, and versatility. The teeth of our gear racks are precisely cut using advanced gear hobbing and shaping techniques, ensuring a perfect mesh with the mating spur gears. This results in smooth and efficient power transmission, minimizing noise and vibration.

We offer a wide range of spur gear racks in different sizes, tooth profiles, and materials to suit various applications. Our standard gear racks are available in both metric and imperial measurements, and we can also produce custom gear racks to meet your specific requirements. The materials we use for our gear racks include high-grade carbon steel, alloy steel, and stainless steel, which offer excellent strength, wear resistance, and corrosion resistance.

In addition to the basic design, our spur gear racks are also equipped with several features to enhance their performance. For example, we offer gear racks with hardened teeth to improve their wear resistance and lifespan. We also provide gear racks with anti-corrosion coatings to protect them from harsh environments.

We are committed to manufacturing spur gear racks of the highest quality. We have invested in state-of-the-art manufacturing equipment and technology to ensure that our production processes are efficient and precise. Our CNC machining centers are capable of producing gear racks with tight tolerances and high accuracy, meeting the most stringent industry standards.

Our manufacturing process is also highly automated, which reduces the risk of human error and ensures consistent quality. We use advanced inspection equipment, such as coordinate measuring machines (CMMs) and gear testers, to verify the dimensional accuracy and tooth profile of our gear racks. This allows us to identify and correct any defects or deviations before the gear racks are shipped to our customers.

Our high-performance spur gear racks find extensive use in a variety of industrial machinery and equipment. In the manufacturing industry, they are used in CNC machines, lathes, milling machines, and other machine tools to control the linear motion of the cutting tools. In the packaging industry, our gear racks are used in packaging machines to move the products along the production line.

In the automotive industry, spur gear racks are used in power steering systems, where they play a crucial role in providing precise and responsive steering. They are also used in other automotive applications, such as windshield wiper systems and window regulators. In the robotics industry, our gear racks are used in robotic arms and other robotic systems to provide accurate and reliable linear motion.

Quality and reliability are the hallmarks of our spur gear racks. We have implemented a comprehensive quality management system that covers every aspect of our manufacturing process, from raw material sourcing to final product inspection. Our quality control team is highly trained and experienced, and they use the latest inspection techniques and equipment to ensure that our gear racks meet or exceed the highest quality standards.

We also conduct rigorous testing on our spur gear racks to ensure their performance and reliability in real-world applications. Our testing facilities are equipped with advanced testing equipment, such as load testers and fatigue testers, which allow us to simulate the operating conditions of our gear racks and evaluate their performance under different loads and speeds.

We understand that every industrial application is unique, and that's why we offer a wide range of customization options for our spur gear racks. Our team of experienced engineers can work with you to design and develop a gear rack that meets your specific requirements, whether it's a custom tooth profile, a special material, or a unique mounting configuration.

We use advanced CAD/CAM software to design and optimize our custom gear racks, ensuring that they are both functional and cost-effective. Our manufacturing facilities are equipped to handle small and large production runs, and we can provide quick turnaround times for custom orders.

We are committed to providing our customers with excellent customer support. Our sales and technical support teams are always available to answer your questions, provide technical advice, and assist you with your gear rack selection and installation. We also offer after-sales support, including maintenance and repair services, to ensure the long-term performance and reliability of our gear racks.

We believe in building long-term relationships with our customers based on trust and mutual respect. That's why we strive to provide the best possible service and support, and we are always looking for ways to improve our products and services to meet the changing needs of our customers.