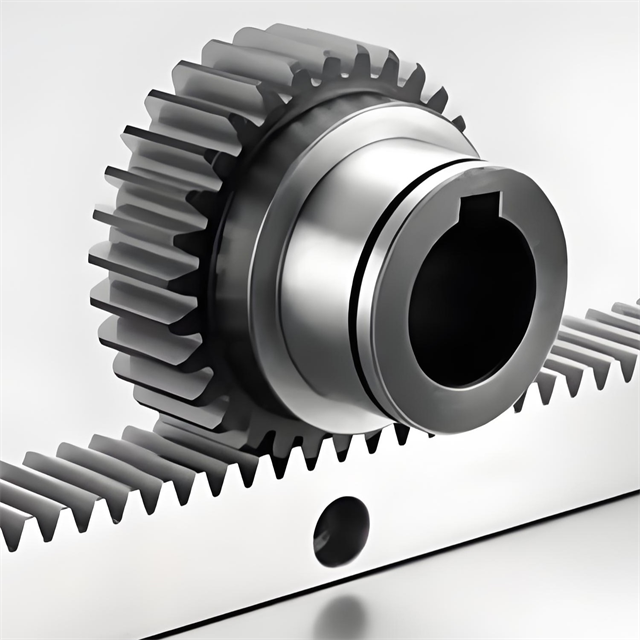

The spur gear transmission relies on the meshing of the driving gear and the driven gear to transmit motion and power. The spur gear is a gear that drives between two parallel axes. Straight cylindrical gears are easy to machine and can produce high-precision gears. Spur gears do not generate thrust (axial force) in transmission, and are one of the most common gears in practical production and use.

| Availability: | |

|---|---|

| Quantity: | |

A spur gear is one of the simplest and most widely used types of gears in mechanical systems. It consists of a cylindrical body with teeth that are cut parallel to the axis of rotation. These teeth are evenly spaced around the circumference of the gear, enabling it to mesh with another spur gear or a rack. When two spur gears are in mesh, the rotation of one gear drives the other gear, transmitting mechanical power from one shaft to another.

The meshing of spur gears is based on the principle of involute tooth profiles. The involute curve ensures smooth and continuous contact between the teeth during operation, reducing friction and wear. This design also allows for a more consistent transmission of torque, making spur gears highly efficient in power transfer. As the gears rotate, each tooth of one gear engages with a corresponding tooth of the other gear, creating a positive drive that minimizes slippage.

At our company, we use only the highest quality materials for manufacturing spur gears. Common materials include carbon steel, alloy steel, and in some cases, non-metallic materials like nylon or plastic for specific applications where noise reduction or corrosion resistance is crucial. Carbon steel is often chosen for its good strength and affordability, while alloy steel offers enhanced mechanical properties such as higher hardness and better wear resistance.

Our manufacturing process involves state-of-the-art techniques. We start with precision machining of the gear blanks to ensure accurate dimensions. The teeth are then cut using advanced gear cutting machines, which can achieve tight tolerances and excellent surface finish. Heat treatment processes, such as quenching and tempering, are applied to further enhance the mechanical properties of the gears, making them more durable and capable of withstanding heavy loads.

Spur gears find extensive use in a wide range of industries. In the automotive industry, they are employed in transmissions, differentials, and engine timing systems. The precise power transmission provided by spur gears is essential for the smooth operation of vehicles, ensuring efficient power delivery to the wheels.

In the manufacturing sector, spur gears are used in machine tools, such as lathes, milling machines, and drill presses. They enable the precise movement of cutting tools and workpieces, allowing for the production of complex parts with high accuracy. Additionally, in conveyor systems, spur gears are used to drive the belts or chains that transport materials, providing reliable and consistent motion.

We understand that every application has unique requirements. That's why we offer comprehensive customization services for spur gears. Whether you need a specific gear ratio, a particular number of teeth, or a custom material, our team of experienced engineers can work with you to design and manufacture the perfect spur gear for your needs.

We can also provide different bore types, such as plain bores, keyed bores, or tapped bores, to suit various shaft connection methods. Additionally, surface treatments like hardening, plating, or coating can be applied to improve the gear's performance, such as increasing its wear resistance or enhancing its corrosion protection.

Quality is our top priority. Our spur gears undergo rigorous quality control checks at every stage of the manufacturing process. From the inspection of raw materials to the final dimensional and functional tests of the finished gears, we ensure that each product meets or exceeds industry standards.

We use advanced inspection equipment, such as coordinate measuring machines (CMMs) and gear testers, to verify the accuracy of the gear dimensions and the quality of the tooth profiles. This commitment to quality ensures that our spur gears are reliable, durable, and perform optimally in your mechanical systems.

Despite our focus on quality, we strive to offer our spur gears at competitive prices. By optimizing our manufacturing processes and sourcing materials efficiently, we are able to provide cost-effective solutions without compromising on quality.

We also understand the importance of timely delivery. Our efficient production planning and logistics management systems enable us to meet tight deadlines and ensure that your orders are delivered on time. Whether you need a single spur gear or a large quantity for a major project, we are committed to providing prompt and reliable service.

Our relationship with our customers doesn't end with the sale. We provide exceptional customer support to ensure that you are satisfied with our products and services. Our team of technical experts is available to answer your questions, provide technical advice, and assist you with any issues you may encounter during the installation, operation, or maintenance of our spur gears.

We value your feedback and are constantly looking for ways to improve our products and services. Whether you have a suggestion for a new feature or a concern about a product, we are committed to addressing it promptly and effectively. Contact us today to experience the difference of working with a reliable and customer-focused spur gear supplier.